Wire Polymer Inner EPDM Tube Copper Fitting

Send Inquiry

The China Wire Polymer Inner EPDM Tube Copper Fitting produced by MING DA HAI CHEN has a closely braided polymer wire on the outer layer, it feels flexible and elastic, is lighter than the traditional metal braided layer, and will not tangle or knot when bent casually during installation. It can be easily adapted to narrow bathroom corners, it has strong tensile and wear resistance, so there is no need to worry about daily bumps and knocks.

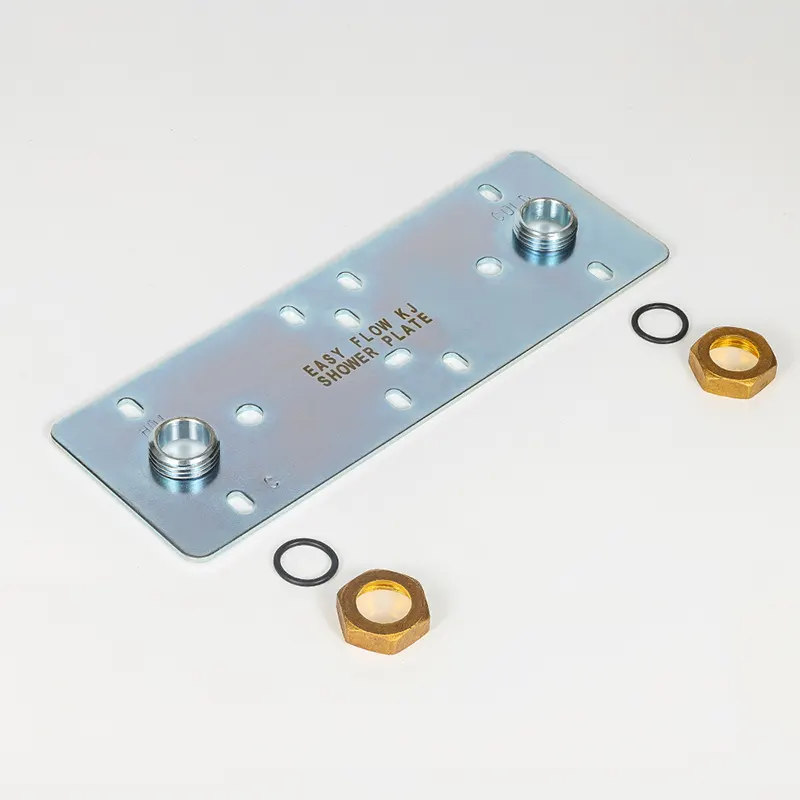

The joint part is made of refined brass, which has undergone precise turning and anti-corrosion treatment, the sealing performance is maximized. After being screwed in place, it basically won't leak water. It can also be adapted to various bathroom equipment interfaces. It is available in a specification of φ 12F1/2M101 and a nominal diameter of DN8, the inner diameter of 1/2 inch is just the industry standard size. The toilet, washbasin and shower head can all be directly connected, the modern and simple design is not picky about the decoration style.

This product of ours has obtained 12 international certifications including DVGW, WRAS and CE, and comes with a 20-year warranty and a loss protection of 2 million US dollars. It is supported by the three major production bases of Feisite in Zhejiang, Nanjing and Vietnam, with a monthly production capacity of 8 million pieces, the delivery time and quality are both very stable.

Precautions

When installing the Wire Polymer Inner EPDM Tube Copper Fitting, pay attention to the nut torque, it is recommended to control it within 60 N.m. Do not tighten it forcefully, otherwise it may damage the sealing structure of the brass joint and cause water leakage.

The inner tube can withstand a temperature of 90℃, but it is advisable to avoid keeping the tube in an environment close to the extreme temperature for a long time, such as directly facing the water outlet of the water heater. High temperatures will accelerate the aging of the material and affect its service life.

Although the outer polymer braided layer is durable, it should be kept away from sharp objects such as scissors, blades and screws. Once the braided layer is damaged, it will affect the pressure resistance performance of the pipe and may cause safety hazards.When cleaning the bathroom in daily life, do not spray strong acid or strong alkali cleaners directly on the pipes, especially the brass joint parts, as it is easy to corrode the surface, affecting the sealing performance and appearance. Just wipe it with clean water.

When storing, it should be placed in a dry and well-ventilated area, away from direct sunlight, and not piled up in a damp or corrosive gas environment. Otherwise, the polymer layer and brass joints are prone to moisture and deterioration.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi العربية

العربية