High-quality and durable Fitting Pipe

Professional Guide to Fitting Pipes: Specifications, Selection, and FAQs

In industrial, plumbing, and construction systems, the integrity and efficiency of the entire network heavily depend on the components used to connect pipes. These critical components, known as Fitting Pipe or pipe fittings, are far from mere connectors. They direct flow, change direction, alter pipe dimensions, and terminate lines, ensuring a secure, leak-proof, and durable system. For engineers, project managers, and procurement specialists, selecting the right fitting is a decision that impacts project longevity, safety, and total cost of operation. This guide provides a detailed, professional overview of Fitting Pipe parameters, supported by specifications and expert FAQs, highlighting the precision engineering behind brands like Ming Da Hai Chen Metal.

Core Parameters for Specifying Fitting Pipe

Choosing the correct fitting requires a thorough understanding of its key parameters. These specifications ensure compatibility with your existing pipework and suitability for the intended service.

Material of Construction

The material defines the fitting's strength, corrosion resistance, temperature tolerance, and application suitability. Common materials include:

Carbon Steel (ASTM A234 WPB): The industry standard for high-strength applications in oil, gas, and steam lines. Offers excellent durability and weldability.

Stainless Steel (ASTM A403 WP316/304): Provides superior corrosion and oxidation resistance. Ideal for chemical, food processing, pharmaceutical, and marine applications.

Alloy Steel (ASTM A234 WP1/WP5/WP9/WP11): Designed for high-temperature and high-pressure services, such as power plants and refineries.

Brass and Copper: Excellent for plumbing, HVAC, and low-pressure decorative applications due to good machinability and corrosion resistance.

Duplex & Super Duplex Stainless Steel: Offer enhanced strength and chloride stress corrosion cracking resistance, used in offshore and harsh chemical environments.

Ming Da Hai Chen Metal specializes in manufacturing fittings from these grades, adhering to international ASTM, ASME, and EN standards to guarantee material traceability and performance.

Frequently Asked Questions (FAQ) About Fitting Pipes

Q: What is the main difference between a "Seamless" and a "Welded" fitting?

A: The difference lies in the manufacturing process. Seamless fittings are formed from a single piece of solid steel billet without any welded seam. This process generally results in fittings with more uniform strength and better performance under high pressure and cyclical loading. Welded fittings are made by bending and welding steel plate or pipe. While modern welded fittings from reputable manufacturers like Ming Da Hai Chen Metal are of high quality and meet all standards, seamless fittings are often specified for the most critical services. The choice depends on the application's pressure, temperature, and code requirements.

Q: How do I select the correct pressure class (e.g., 150, 300, 600) for my application?

A: The pressure class selection is based on the design pressure and temperature of your piping system. You must consult the applicable piping code (e.g., ASME B31.1 for Power Piping, B31.3 for Process Piping) and the pressure-temperature rating tables provided in standards like ASME B16.5 (for flanges) or B16.34 (for valves/fittings). These tables show the maximum allowable non-shock working pressure at a given temperature for each class. A Class 300 fitting will have a higher pressure rating at the same temperature than a Class 150 fitting. An engineer typically performs this calculation to ensure safety and compliance.

Q: When should I use an Eccentric Reducer versus a Concentric Reducer?

A: This is a crucial practical decision. A Concentric Reducer, which is symmetrical around the centerline, is used in vertical pipe runs or where air accumulation is not a concern. An Eccentric Reducer has one flat side, allowing it to maintain a constant bottom-of-pipe or top-of-pipe elevation. Use an eccentric reducer with the flat side on top in horizontal pump suction lines to prevent air pockets. Use it with the flat side on the bottom in horizontal drain lines to prevent sediment accumulation. This ensures smooth flow and avoids operational issues.

Q: What certifications should I look for when sourcing industrial pipe fittings?

A: Reputable manufacturers provide certifications that validate product quality and traceability. Key certificates include:

- Material Test Certificate (MTC/MTR): A mill report verifying chemical composition and mechanical properties of the raw material.

- Certificate of Conformity (CoC): States the product conforms to the ordered specification (e.g., ASTM A234).

- Third-Party Inspection Reports: From agencies like SGS, BV, or Lloyd's Register, confirming dimensions, testing, and marking.

- ISO 9001:2015: Indicates the manufacturer has a certified Quality Management System in place.

Q: How do I ensure weld quality when installing butt-weld fittings?

A: Proper welding is critical for joint integrity. Key steps include:

- Fit-Up: Ensure proper alignment and a consistent root gap between the fitting bevel and the pipe bevel.

- Cleaning: Remove all rust, paint, oil, and moisture from the welding zone (inside and out).

- Welding Procedure Specification (WPS): Use a qualified WPS suitable for the fitting and pipe material. Welders should be certified.

- Consumables: Use the correct electrode or filler wire (e.g., E7018 for carbon steel).

- Post-Weld (if required): For certain alloy steels, post-weld heat treatment (PWHT) is necessary to relieve stresses.

Q: Can I mix fitting brands within the same piping system?

A: While it is technically possible if all fittings meet the same ASTM/ASME dimensional standards, it is generally not recommended for critical systems. Mixing brands can lead to slight variations in material chemistry, heat treatment, or dimensional tolerances that may affect long-term performance and weldability. For consistency in quality, traceability, and appearance, it is best practice to source all fittings for a specific project or system loop from a single, reliable manufacturer like Ming Da Hai Chen Metal.

Why Precision in Fitting Pipe Selection Matters

The selection of Fitting Pipes is a fundamental engineering task. An underspecified fitting can lead to leaks, ruptures, and costly downtime, while an overspecified one unnecessarily increases project capital expenditure. By understanding the detailed parameters—material, type, size, pressure rating, and end connection—you make informed, cost-effective, and safe decisions. Partnering with a manufacturer that prioritizes strict adherence to international standards, rigorous testing, and material traceability, such as Ming Da Hai Chen Metal, provides the technical assurance required for successful project execution and long-term operational reliability.

- View as

½×¾ Long Bath Shoe Gasket

½×¾ Long Bath Shoe Gasket play a significant role in family life. Correct installation and use of gaskets can prevent water leakage and ensure the safety and comfort of family life. When choosing the material and installation method of the gasket, the decision should be made based on the actual situation. If you have any questions, you can leave a message to consult us for professional help.

Read MoreSend Inquiry½×¾ Lengthened Bath Shoe Gasket

The ½×¾ Lengthened Bath Shoe Gasket is a round rubber pad, usually used at the connection between the shower head and the shower hose. Its main function is to prevent water leakage and ensure the safety and comfort of family life. Shower head gaskets are usually made of materials such as rubber and silicone, and are also known as gaskets, sealing gaskets, etc.

Read MoreSend Inquiry½×¾ Short Bath Shoe Gasket

½×¾ Short Bath Shoe Gasket can effectively prevent water leakage and ensure the safety and comfort of family life. If a gasket is not installed at the connection between the showerhead and the shower hose, water will seep out from the interface, causing problems such as dampness, mold and rot on the walls and floors. In the long run, it will also affect the hygiene and health of the family.

Read MoreSend Inquiry⅜×½ Bath Shoe Gasket

When you install a faucet, the connection sequence is usually like this (from top to bottom)Faucet body → Install gasket → countertop/sink → Fix nut/bolt (tighten from the bottom).The ⅜×½ Bath Shoe Gasket is at a crucial position that connects the upper and lower parts.

Read MoreSend InquirySquare Shower Mounting Kits

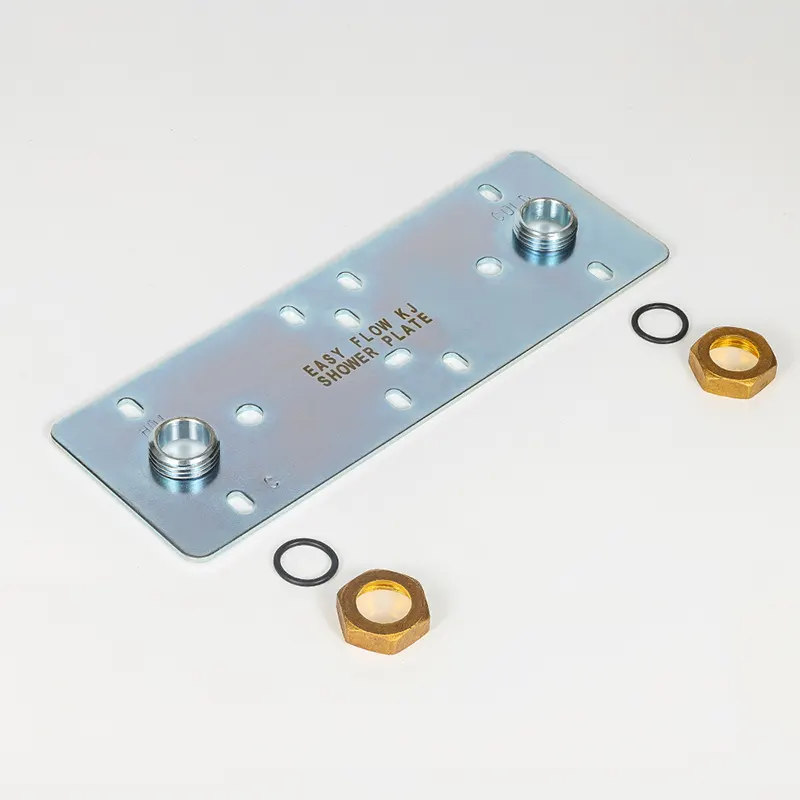

This high-quality square shower mounting kits designed by MING DA HAI CHEN for the UK market offers a complete and reliable installation solution for bathroom faucets. It is not a single part but a combination of various composite material accessories like brass connectors and carbon steel fixed plates, designed to make the installation process of the faucet more stable and convenient. The set supports customizing your brand logo in a prominent position, making it suitable for batch engineering needs in places such as hotels and schools.

Read MoreSend InquirySilver Shower Plate

MING DA HAI CHEN as the Chinese top leader manufacturing shower plate, designed for the UK market this silver shower plate fix to simplify the installation of a wall-mounted faucet or shower panel, The core components are consist of as high-quality brass connectors and robust mounting panels, providing customers with a complete solution. It can adapt to a variety of use scenarios such as hotels, schools and family bathrooms, and significantly improve the construction efficiency while ensuring the installation is firm and reliable.

Read MoreSend Inquiry English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi العربية

العربية