Polished Chrome Angle Valve

Send Inquiry

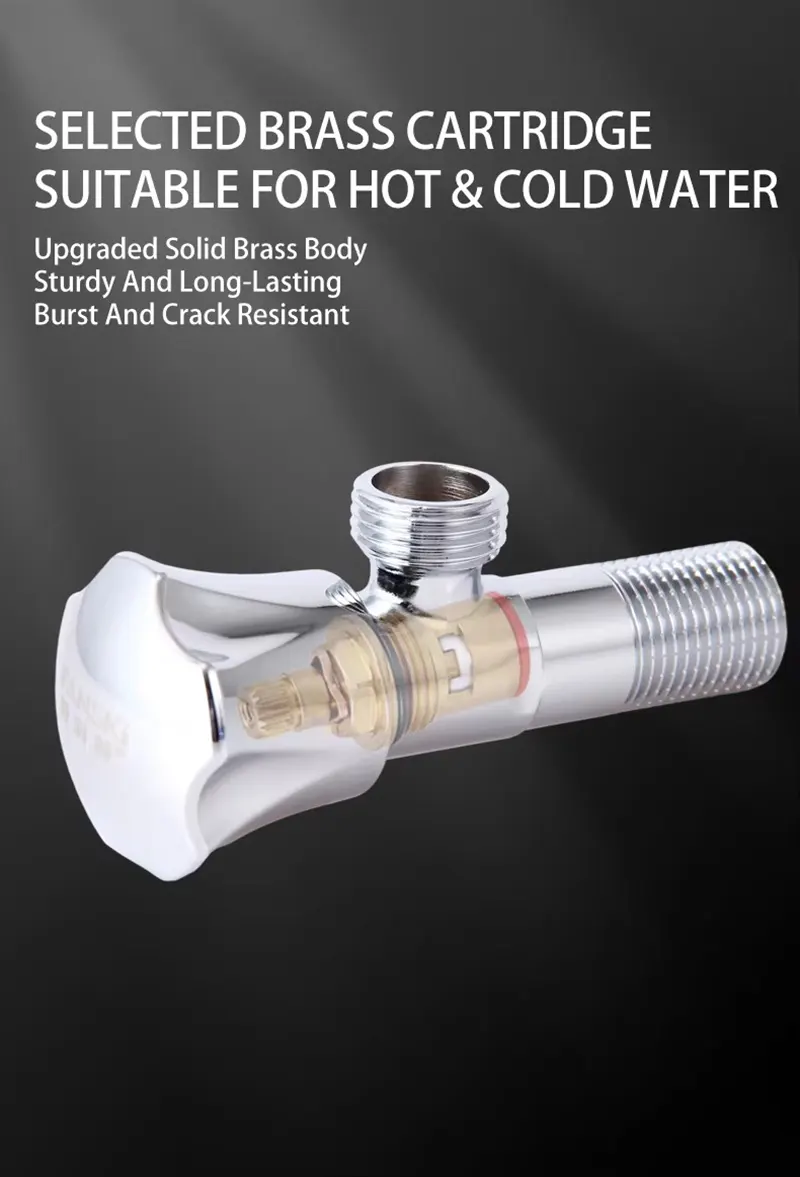

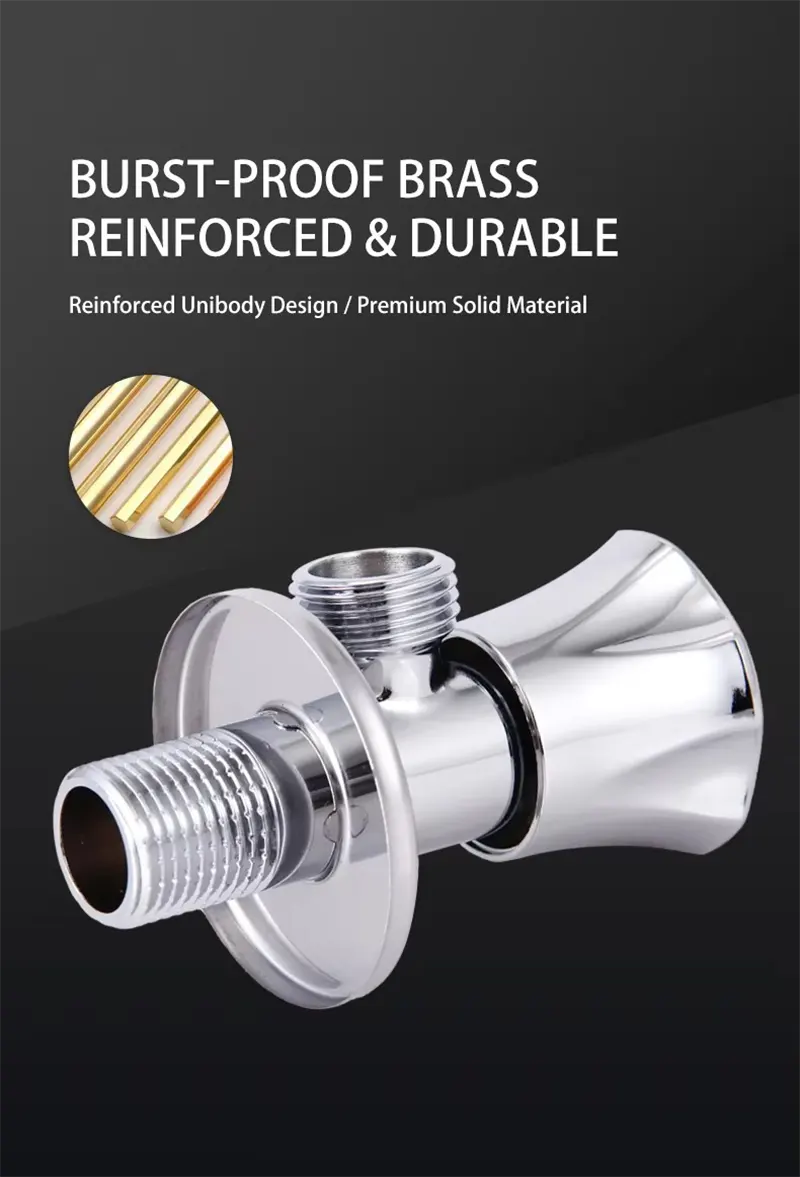

Our standard polished chrome angle valve is designed to connect hot and cold water lines. The valve body is cast in one piece of upgraded solid brass, providing a robust structure to withstand daily water pressure and prevent blowouts.The surface of the product is treated with three layers of high quality electroplating: the bottom layer is an anti-corrosion nickel layer, and the top layer is a high gloss chrome finish, providing excellent anti-corrosion and rust performance.The valve core is made of brass suitable for hot and cold water to ensure reliable sealing.The product complies with the international standard of G1/2 connection and is easy to install. It is designed to provide users with a basic but vital waterway control point through enhanced materials and precise manufacturing processes.

Product Feature

The characteristic of this polished chrome angle valve lies in its enhanced durability of the base structure. The solid one-piece formed brass valve body is its core advantage, which fundamentally enhances the overall strength and pressure resistance of the product and reduces the risk of leakage caused by weak structure. The three-layer electroplating process not only endows the product with a bright and long-lasting appearance, but more importantly, it builds a long-lasting anti-corrosion system from the base material to the surface, which can effectively resist the erosion of humid environments such as kitchens and bathrooms. The overall design returns to the essence of practicality, without any redundant functions. It focuses on solving the common problems of rust and leakage of Angle valves through high-quality solid materials and strict protective processes, striving to become a reliable component in household pipelines that does not require frequent maintenance.

Product Parameters

|

Product Name |

Angle Valve |

|

Specification |

M1/2"×M1/2" |

|

Material of Body |

Refined Brass |

|

Material of Cartridge |

Ceramic |

|

Material of Handle |

Refined Brass |

|

Finish / Surface |

Chromed |

|

Nominal Pressure |

PN10 |

|

Max. Operating Temperature |

90°C |

|

Warranty |

20 Years |

|

Liability Coverage |

USD 2 Million |

|

Logo |

Customized logo welcomed |

|

Packing |

Standard export package or customized |

Application Suggestion

The correct selection and use of angle valves can better bring out their performance and extend their service life. This angle valve is suitable for the vast majority of households where independent control of the waterway is required. Its main application scenarios include connecting the water inlet of the toilet, the cold water pipe interface of the water heater, and the faucet hose under the kitchen sink or washbasin.

Firstly, It is recommended to close the main water valve first before installation. When installing, an appropriate amount of raw material tape (usually 15 to 20 turns) should be wound clockwise around the threaded part of the Angle valve to enhance the sealing performance. Screw the Angle valve into the pre-embedded interface in the wall by hand. After feeling it tightened, use a wrench to reinforce it for about half a turn. Do not apply excessive force to avoid damaging the threads or the valve body. After installation is completed, first slowly open the Angle valve to let water flow, check if there is any leakage at the connection points. After confirming that there are no errors, connect the equipment hose and use it normally.

Secondly, the installation location should be kept ventilated and dry as far as possible. Although the product has electroplating protection, the appearance may still be affected by the extreme humid environment for a long time.Finally, after connecting the hose, the main valve can be slowly opened for water, and check the interface for leakage to ensure that the installation is in place.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi العربية

العربية