Stainless Steel Flexible Hose

Send Inquiry

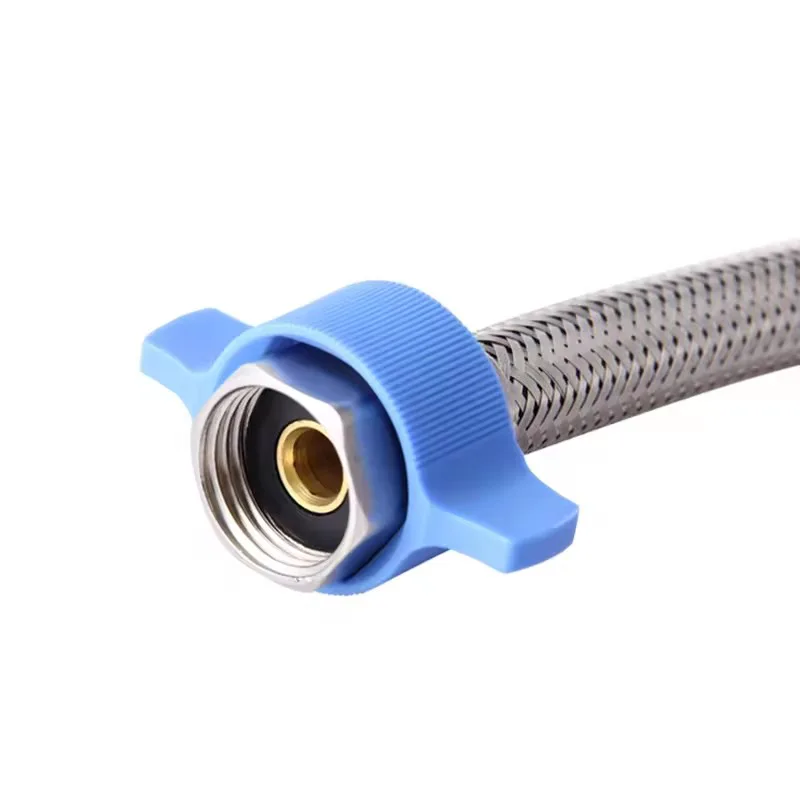

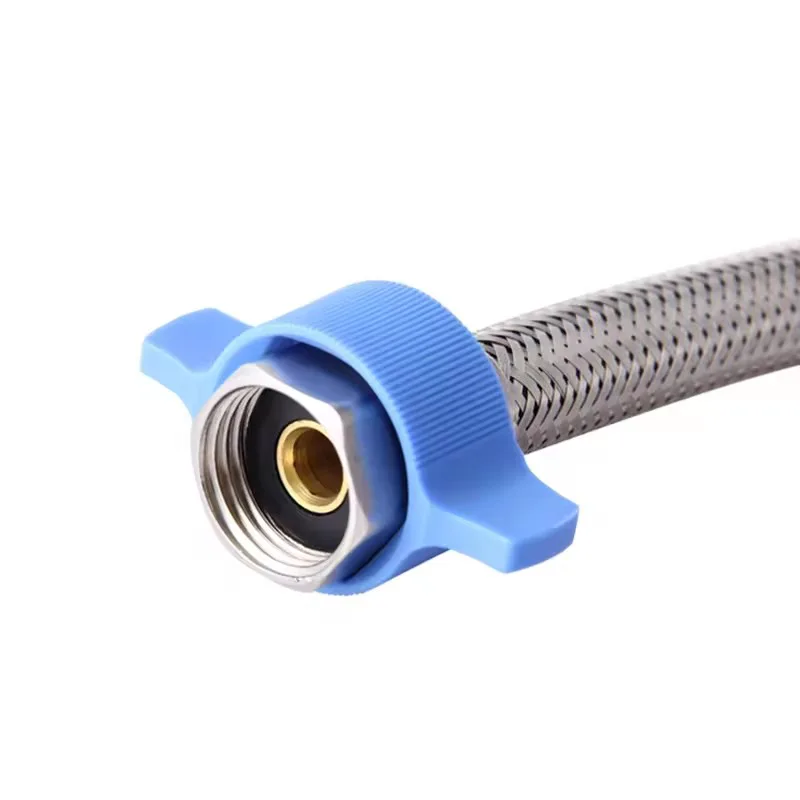

MING DA HAI CHEN stainless steel flexible hose made in China is a reliable choice for kitchen water connections.It uses 7 strands of 0.18mm 304 stainless steel wire tightly woven into the outer tube, providing excellent tensile and explosion-proof protection.The inner tube is EPDM rubber material with a wall thickness of 2 mm, with a fracture strength of more than 9 MPa, and can withstand a working pressure of 1.0MPa and water temperature below 90 ° C.

The connectors at both ends are made of precision forged brass thickened nuts, and the leak-proof sealing ring is built in to effectively prevent leakage of the interface.The product conforms to GB/T 23448-2019 standard and has the characteristics of health and environmental protection. It is suitable for connecting kitchen faucets, basin faucets and other water equipment to provide safe and stable water supply.

Product parameters

|

Parameter |

Specification |

|

Material (Outer) |

304 Stainless Steel |

|

Inner Diameter |

1/2 Inch |

|

Maximum Working Pressure |

1.0 MPa |

|

Maximum Working Temperature |

90 °C |

|

Application |

Bathroom, Kitchen |

|

Design Style |

Modern |

|

Features |

Flexible & Durable, Easy to Install |

|

After-Sales Service |

Online Technical Support |

|

Place of Origin |

Zhejiang, China |

|

Logo/Graphic |

Laser Printing |

|

Inner Tube Material |

EPDM |

|

Braiding Material |

SUS304 |

|

Terminal Material |

Refined Brass |

|

Size |

F1/2 × F1/2 |

|

Nominal Diameter |

DN10 |

|

PCS/CTN |

100 |

Installation Steps Instructions

Preparations:

Close the water source valve and get the installation tools ready.Check the appearance of hoses and joints for no damage, creases or distortions, and confirm that the sealing rings at both ends are intact.

Connection and installation:

Align one end of our stainless steel flexible hose with the faucet interface and tighten the nut by hand to ensure the threads are aligned.The other end is connected in the same way to the Angle valve or water intake.

Reinforcing seal:

Use the dedicated wrench provided. On the basis of manual tightening, align the nut and then rotate it for reinforcement by approximately 1/4 turn.Be careful not to pressure, so as not to damage the threads.

Check test:

open the water valve, observe the joint leakage.If there is dripping water, turn off the water source and then fine-tune the nut tightness. Test again until it is completely sealed.

Note for use:

During installation, avoid sharp objects, maintain the natural arc of the hose, and avoid small Angle bending.When used in damp environment, ensure outlet dry ventilation.

English

English Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi العربية

العربية